The peak of all-round performance. The HT2.5 (Holy Toledo 2.5) maintains its design towards everyday conditions, only with added spark! After a request from Filipe to make the HT2 go as fast as possible, Marcio got to work.

There have been a few minor tweaks throughout the model, with the biggest being in the tail. A small channel has been added just behind the back fin. This channel has created three major enhancements, speed - bite - drive. When surfing off the back foot there will be a considerable amount of squirt and drive without sacrificing any grip. The HT2.5 is the peak off all-round performance.

- SMALL WAVE - MEDIUM WAVE

| LENGTH | WIDTH | THICKNESS | VOLUME |

|---|---|---|---|

| 5'0 | 19 | 2 5/16 | 24.7L |

| 5'2 | 19 1/4 | 2 3/8 | 25.9L |

| 5'4 | 19 1/2 | 2 7/16 | 27.6L |

| 5'6 | 19 3/4 | 2 1/2 | 29.5L |

| 5'8 | 20 | 2 1/2 | 30.8L |

| 5'10 | 20 1/4 | 2 11/16 | 34.1L |

| 6'0 | 20 1/2 | 2 11/16 | 36.2L |

| 6'2 | 20 3/4 | 2 11/16 | 38.4L |

| 6'4 | 21 | 2 7/8 | 42.1L |

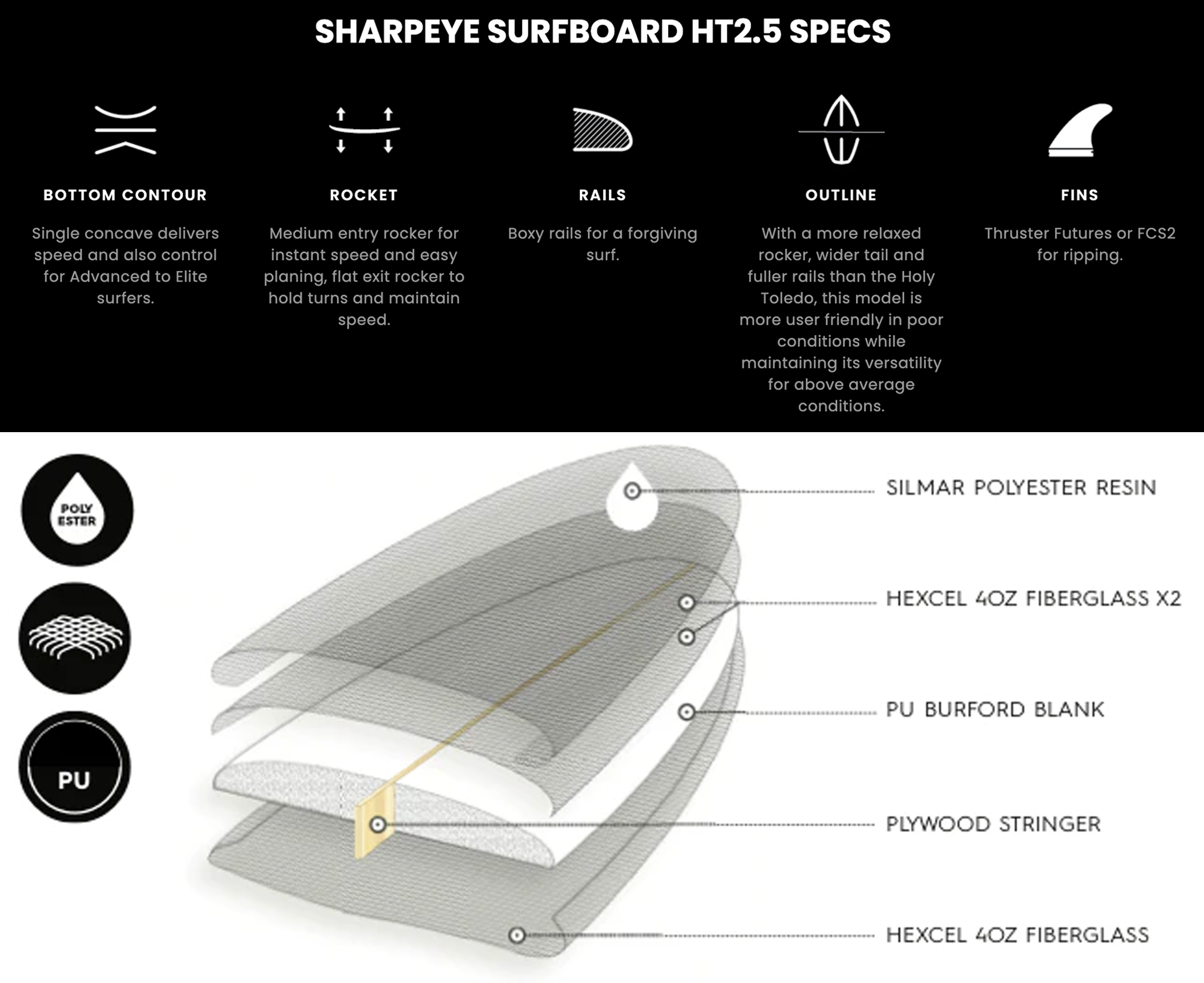

PU CONSTRUCTION PU construction by Euroglass. The “P” gets its name from both the resin and the foam: polyester resin and the “U” comes from polyurethane foam . PU is the traditional surfboard construction since foam core surfboards were invented. It is still the most widely used construction method today. PU is often incorrectly referred to as “fiberglass” construction – the reason this is incorrect is because the same exact fiberglass cloth is used in both PU and Epoxy construction types, it’s the foam core and resin that soaks into the fiberglass cloth (and foam) that differ. While PU construction is generally slightly heavier and isn’t quite as strong as Epoxy construction, it tends to have a more reliable and predictable feeling whilst surfing. This is due primarily to a slower flex pattern and denser foam than epoxy construction, which basically causes less “surprises” and more predictability while surfing, especially when making hard or sharp turns. PU construction tends to be more naturally conducive to color work, especially translucent resin tints. PU is also a bit less sensitive to water infiltration and heat than epoxy construction.

PU CONSTRUCTION PU construction by Euroglass. The “P” gets its name from both the resin and the foam: polyester resin and the “U” comes from polyurethane foam . PU is the traditional surfboard construction since foam core surfboards were invented. It is still the most widely used construction method today. PU is often incorrectly referred to as “fiberglass” construction – the reason this is incorrect is because the same exact fiberglass cloth is used in both PU and Epoxy construction types, it’s the foam core and resin that soaks into the fiberglass cloth (and foam) that differ. While PU construction is generally slightly heavier and isn’t quite as strong as Epoxy construction, it tends to have a more reliable and predictable feeling whilst surfing. This is due primarily to a slower flex pattern and denser foam than epoxy construction, which basically causes less “surprises” and more predictability while surfing, especially when making hard or sharp turns. PU construction tends to be more naturally conducive to color work, especially translucent resin tints. PU is also a bit less sensitive to water infiltration and heat than epoxy construction.