The Great White Twin is a fast short board with two fins whose design is inspired by the silhouette of the Great White Shark. Kelly Slater designed the "Great White Twin" with I-Bolic technology and Volcanic lamination together with shaper Mike Woo. The technology chosen for this new shape is I-Bolic with Volcanic lamination, Firewire's ecological alternative to the use of carbon, to enhance its performance.

It is a high performance groveler with a three fin set up, it is proposed as Twin +1 and can be combined with the KS Twin + 2 fin set, which includes in addition to the two lateral twin fins, two additional small central fins use alternatively one to the other, also very soon available on the Surfcorner Store.

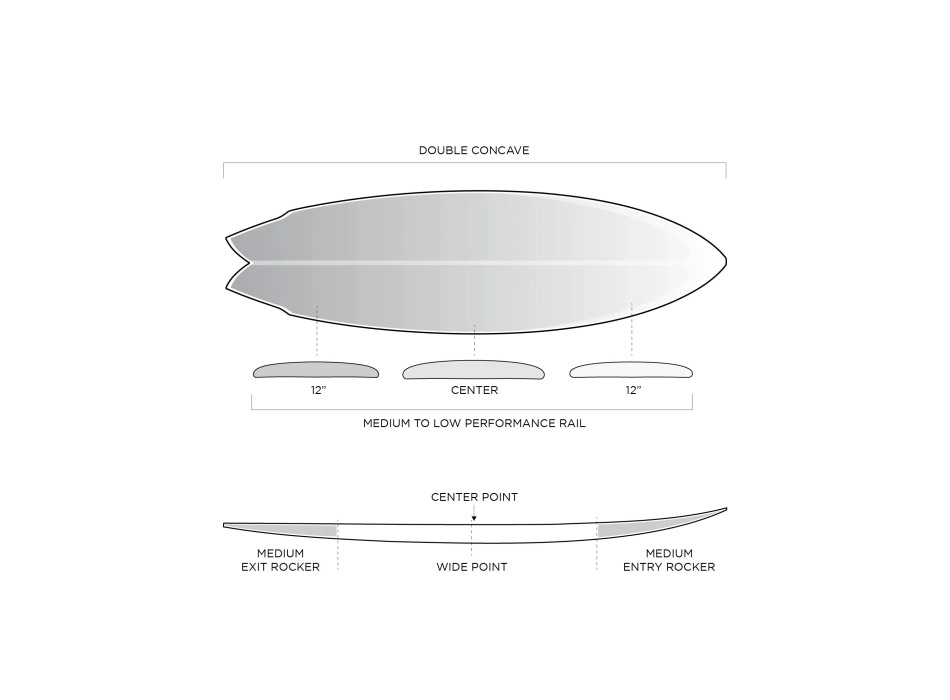

The Great White promises the paddling and launching of a hybrid and the rail performance of a shortboard. It fits well in the pocket and is perfect and fast in the tubes. It fits where most fish can't, creates speed on soft waves, controls speed on powerful waves and excels at tight turns in punchy pockets and quick changes on shoulder sections.

Its volume is hidden in the center with thin edges for immediate response and quick reaction in the pocket. She has the speed of a twin fin with the immediate response of a Thruster, and her raised tail rocker makes her magical when surfed backside. Another strong point is the low resistance if used without the central rear fin or minimal resistance if with a smaller rear fin.

Recommended with the same volume as your performance shortboard, or slightly more.

"The concept of the Great White came from an idea that Kelly had.

One evening during dinner she showed me a photo of a great white shark and asked if I could incorporate the curves of a top predator into a table design.

A little surprised I listened to her idea of transforming all this into a performance twin.

With the photo in hand, I worked on the outline of the board, following the curves and movement of the shark in order to visually balance them with some dimensions I had in mind.

Talking to Kelly we positioned the wings until we found a good balance.

Regarding the width, we decided to achieve the adequate lift needed with simple bottom contours. I decided to use my best performance board rocker that I have developed and evolved over the last 20 years.

Outline, rocker, bottom contours all in balance with each other.

I'd love to tell you how we spent years developing the design, but the truth is that the first shape was magical..." - Woo

WHAT IS I-BOLIC TECHNOLOGY ?

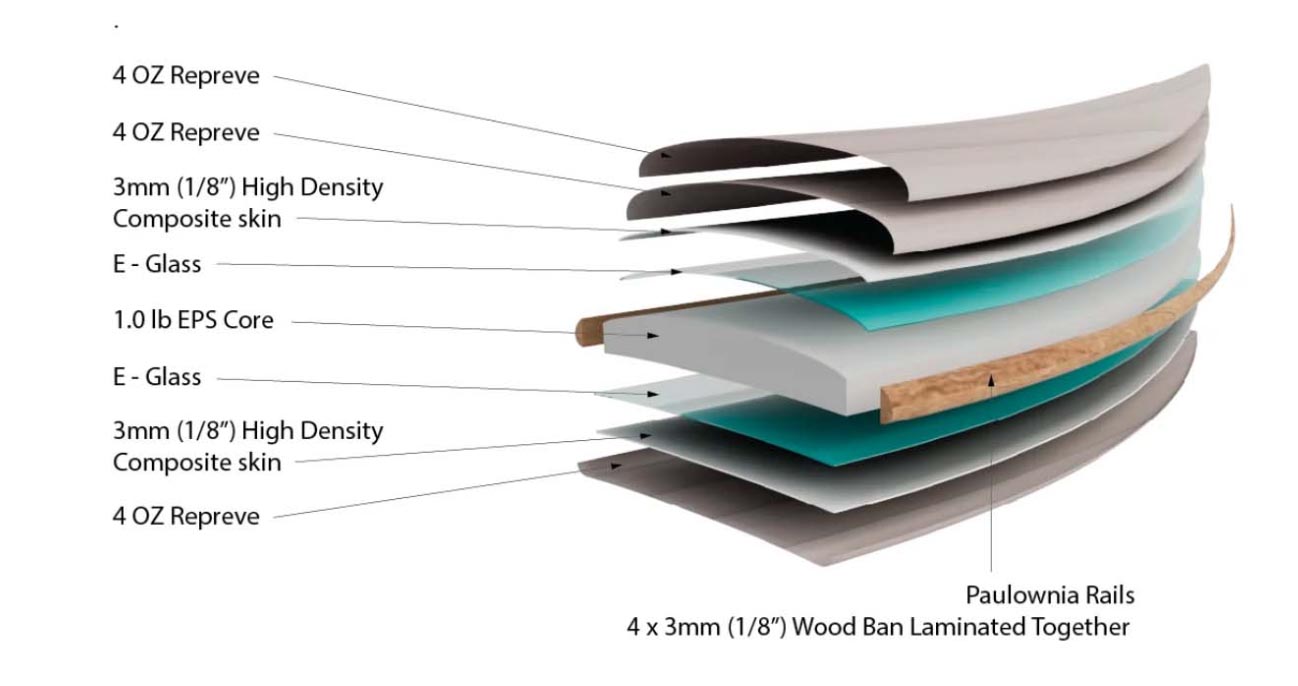

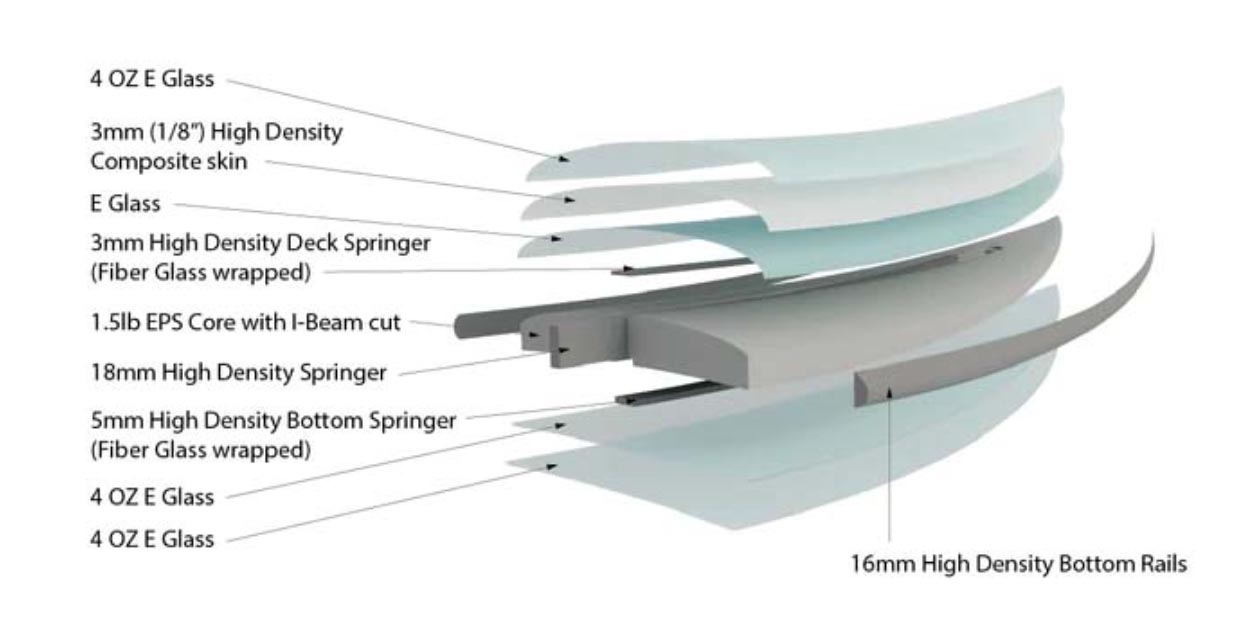

I-BOLIC is a patent-pending technology incorporated into the internal structure of the board that creates predefined structural flexibility along with a strong, long-lasting structure. I-BOLIC technology is an engineering feat that integrates performance into the core of your surfboard - no external carbon layers or heavy laminations required. A leap forward in surfboard manufacturing with an interplay of our favorite elements of LFT and Helium combined, elevated and improved to put the future beneath your feet.

Fiber Reinforced I-Beam down center with Parabolic Rail Springers from nose to tail.

Three independent points for flex control and break resistance

I-Beam ensures firmness underfoot and unparalleled break strength

Two Parabolic Rail Springers enable flex and recoil during turns

VOLCANIC TECHNOLOGY

"Firewire Volcanic is the new production technology from Firewire Surfboards that improves the speed, control, response and resistance of your surfboards. Firewire Surfboards never stops innovating both in processes and in the inclusion of new materials, to obtain surfboards with the best performance/durability ratio on the market. This new technology that Volcanic brings to the market, thanks to the incorporation of new materials, promises to offer more speed, better response and greater resistance. The new volcanic lamination of Firewire offers performance similar to carbon fiber in terms of weight, flexibility and response.But unlike this, basalt fiber which comes from purely organic materials combined with bioresin, is an ECO alternative to the use of carbon fiber fabric and of standard epoxy resin."

Volcanic Tech is made of extruded basalt fibers, volcanic rocks that are chopped, melted and extruded into woven fibers that make up the cloth. The manufacturing of basalt requires the melting of cleaned and pulverized basalt rocks at approximately 1,500 C° (2,730 F°). Molten rock is extruded through small nozzles that produce continuous strands of basalt fiber. These filaments are then cut into long stem fibers and woven into cloth for laminating the boards. The cloth has similar characteristics to carbon in terms of weight and resistance, but considering that the fibers derive from raw materials of an organic nature, when they are combined with organic resins they create an ecological alternative to traditional carbon fiber cloths.

Basalt fiber has been around for decades, but is relatively new to fiber-reinforced polymers (FRP) and structural composites when it comes to building surfboards.

It has a chemical composition similar to fiberglass but with greater resistance capacity and unlike most glass fibers, it is highly resistant to alkalines, acids and salt, making it an excellent candidate for the creation of surfboards .

Compared to carbon and armide fiber, it has a much wider usable temperature range, ranging from -452° F to 1,200° F (-269° C to +650° C), greater resistance to oxidation , radiation, compression and shear.

Cloth can withstand higher temperatures than carbon fiber, this leads to its frequent use in the aerospace industry for the creation of rockets and jet engines.

Its elasticity characteristics are higher than a classic carbon fiber, therefore allowing the board to have more flexibility for a natural feel underfoot.